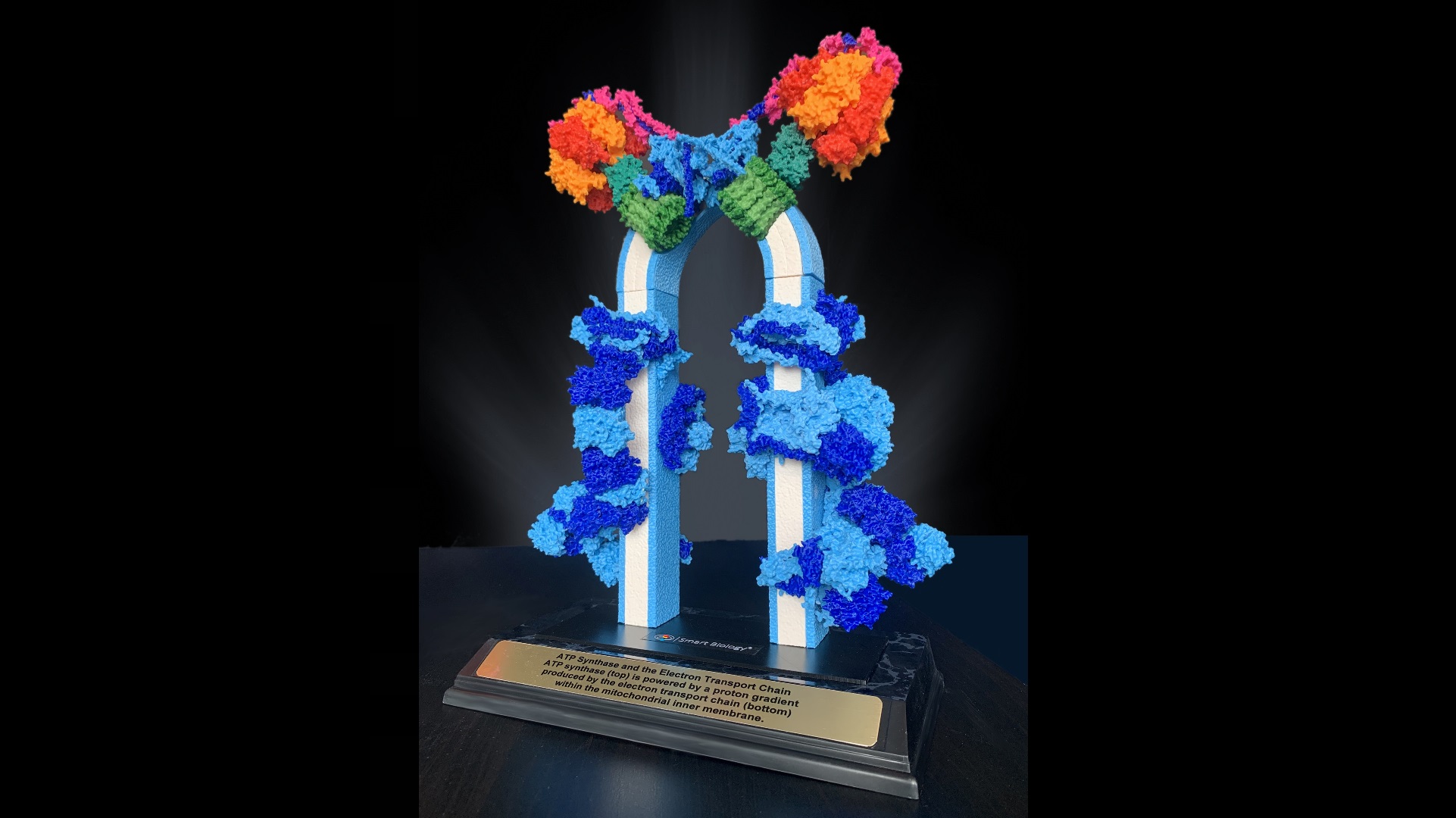

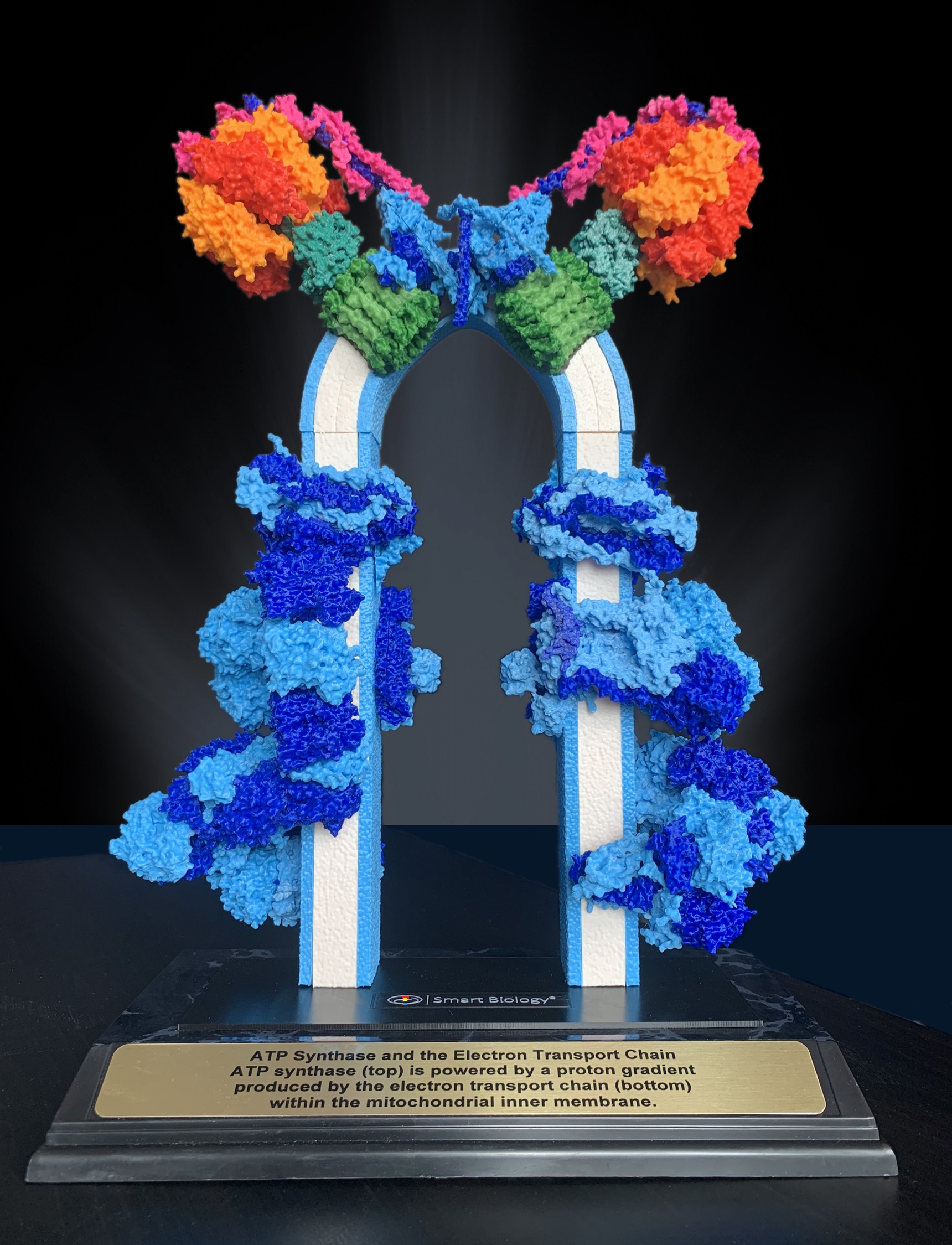

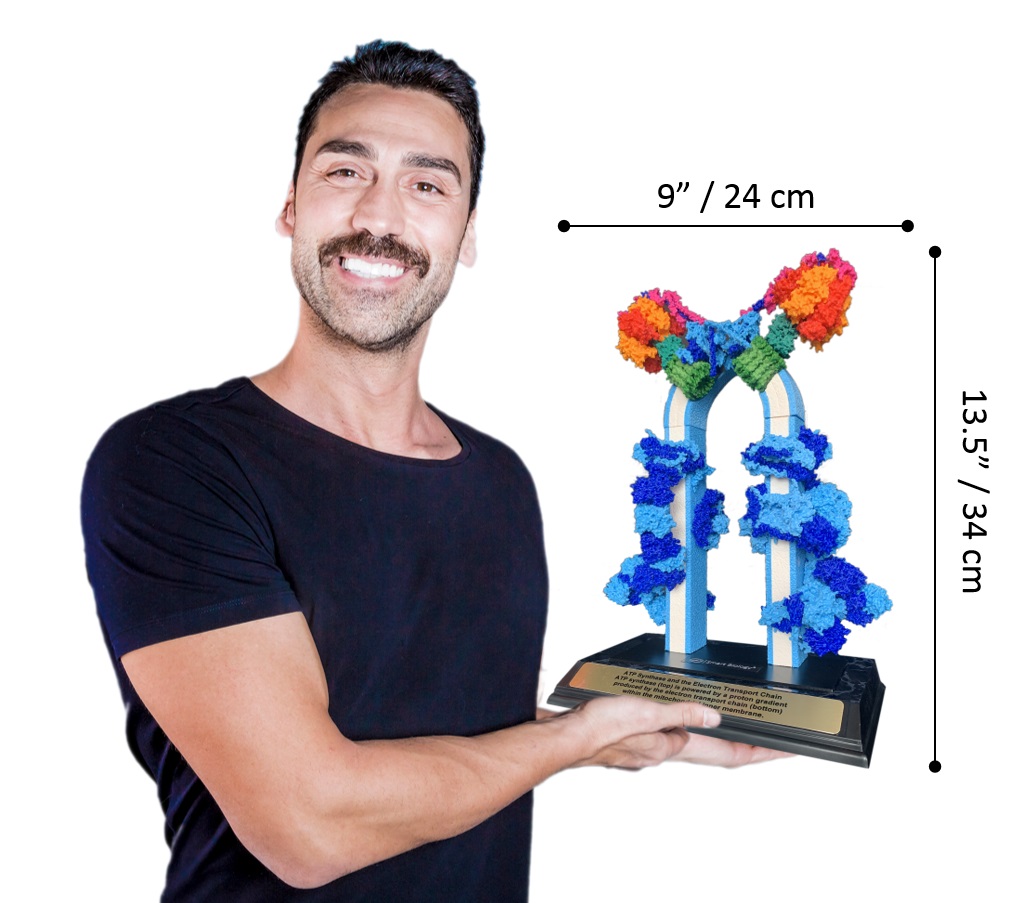

For those looking for an even bigger centerpiece then the ATP synthase dimer, the ATP synthase and ETC is a massive structure that is hand-assembled with great care from 208 individually 3D-printed parts in 11 different colors. The structure measures 9 1/4″ (23.5 cm) wide by 4 7/8″ (12.5 cm) deep by 13 3/8″ (34 cm) tall. Please read the product description below, and please click here for more images and information.

3D Printed ATP Synthase and the Electron Transport Chain (ETC)

$2,350.00

(USD)Description

Whether you have the large ATP synthase model or the extended ETC addition, we put great care into the production and assembly of every piece. The process begins with a model of the entire structure in 3D space. This ATP model is based on the scientific structures 6BH8, 1C1F, 1E79, and 2WSS from the Protein Data Bank (PDB) (www.rcsb.org).

Next, using 3D software, we break the model up into separate pieces based on color. Almost every piece is then sliced in half so that it can be printed lying flat on the print bed, and glued together with its other half once all of the printing is complete. During the design process, each piece undergoes several rounds of printing, with each round serving as a learning experience as to how the pieces will fit together as a whole. During this refinement process, we add clasps, holes, knobs, and other features to the pieces so that they will all stay together once glued.

Once this design work is complete, it’s time to actually print the final pieces in each color. Each individual piece is printed with a 0.2 mm nozzle and 0.12 mm layer height to ensure that the fine detail of this structure comes through on the final product. Support structures are then removed from each piece, and the parts are fastened and glued together one at a time, and with great care and attention to detail. This means that every model is hand assembled by an experienced artist.

Finally, once the entire structure is complete, compressed air is used to remove any dust that might be present and it is carefully placed in a plastic bag which is then carefully wrapped in bubble wrap. This well-padded structure is then placed inside a sturdy box filled with packing peanuts for further support during transportation.